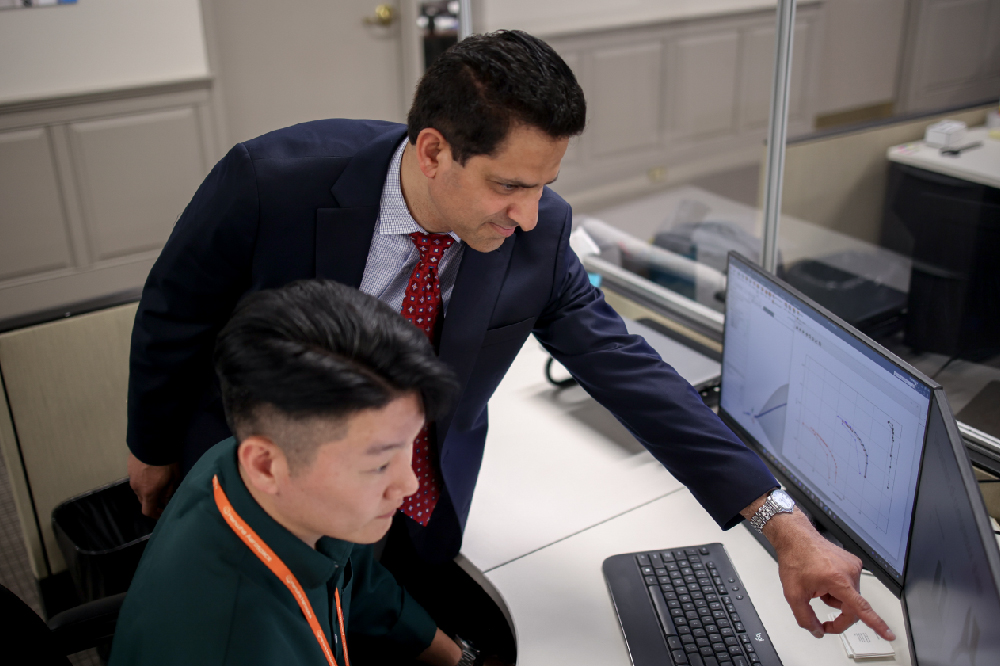

The heart of a jet engine: Anil Prasad of Hanwha Aerospace USA shares his insight

As the new chief engineer in charge of compressors at Hanwha Aerospace USA, Anil Prasad took time out of his busy schedule to talk about his recent career transition. What motivated him to move to Hanwha after 27 years at another aerospace company?

Q. Thank you for joining us today. I know you’re new to Hanwha. Can you tell us a little bit about yourself?

Yes, of course. I joined Hanwha Aerospace USA in December, having worked at Pratt & Whitney for 27 years before that. I have a Ph.D. from Cornell University, and I’ve lived in Connecticut for nearly 28 years. I enjoy reading, tennis, swimming, traveling, experiencing other cultures and cuisines, and spending time with my family.

Q. What attracted you to the aerospace industry?

My primary area of expertise is aerodynamics, a subject that has always fascinated me. My interest really got started during my second and third years of university when I took introductory courses in fluid dynamics, aerodynamics, and wing theory. Milton Van Dyke’s book “An Album of Fluid Motion” contained stunning flow visualization photographs of fluid flow past various objects — over wings, and through pipes and nozzles. I was in complete awe of how nature behaved, and I decided to follow my passion.

Q. And your passion for aerodynamics turned into a career?

That’s right. Aerodynamics became the focus of my doctoral studies. Later, at Pratt & Whitney, I was heavily involved in the research and development of jet engines, with a particular interest in compressors and fans. I was fortunate to be able to produce papers on the subject based on high-fidelity simulations. Then I went on to present them at international conferences and publish them in international peer-reviewed journals.

My fascination with aerodynamics persists in my current role at Hanwha Aerospace, where I continue to learn about aspects of fans and compressors that go beyond my primary area of expertise. The aerodynamics of a compressor — the part of an aircraft engine that increases the pressure of the incoming air before it reaches the combustion section — are especially fascinating and challenging.

“My fascination with aerodynamics persists in my current role at Hanwha Aerospace, where I continue to learn about aspects of fans and compressors that go beyond my primary area of expertise.”

Q. Really? Why is that?

I’m fascinated by the wide variety of flow phenomena experienced by the compressor over the operating range of the engine. A compressor is the heart of a gas turbine engine. It needs to perform reliably throughout a flight — taxiing, takeoff, climb, cruise, and descent. And it’s right near the front of the engine, so it directly encounters the flow ingested from the atmosphere, be it during level flight at altitude, through a dust storm, flying in rain or hail, or during aircraft maneuvers.

All of this makes for a challenging module. The compressor must be robust, affordable, and maintainable through the engine life cycle. It also needs to meet multiple, sometimes conflicting, disciplinary requirements. Fielding a robust compressor design costs many millions of dollars. But that investment can be leveraged many times over, since the same compressor design can be reused.

Q. Is there any past accomplishment involving compressors that you would like to share with our readers?

Nearly 10 years ago, when I was a manager in the compressor group at Pratt & Whitney, I recognized the need to improve our design system to meet challenging new requirements. Everyone was aware of the limitations of the existing system, but no one had taken the initiative. I proposed a new system, secured funding for it, and empowered a few enthusiastic engineers to create it. Within a few short months, Pratt & Whitney had designed some very challenging compressors and fans under this new system, which is still in use today.

I’m proud that the team I assembled worked in an agile manner, that its work had a positive impact on an ongoing program, and that it delivered viable designs in a fraction of the time that the legacy system would have taken.

Q. Why did you move to Hanwha?

I moved to Hanwha for the opportunity to form and lead a team that will design compressors and fans for Hanwha Aerospace products. It was a big step, but I’m a change agent at my core. I fundamentally believe that no matter one’s current state, there are always opportunities to do better. I learn best by constantly challenging myself — by pushing past my comfort zone. I’m thrilled to be working with talented, open-minded individuals who care for each other.

Q. Are there any big changes ahead at Hanwha that you can tell us about?

In conjunction with Hanwha Aerospace in South Korea, we plan to harness Hanwha’s advanced, cost-effective machining capabilities to design and develop a next-generation aero-engine. Although the requirements for this engine are being settled, the design will be challenging for both the fan and the compressor, and the engine will be cost competitive to products already available.

The development of the fan and compressor for the next-generation aero-engine will place South Korea on the map of worldwide engine manufacturers. It will help the local economy by attracting top talent to Hanwha Aerospace and Hanwha Aerospace USA.

The fact that I will be responsible for designing a module for Hanwha’s next-generation aero-engine is a dream.

“I fundamentally believe that no matter one’s current state, there are always opportunities to do better. I learn best by constantly challenging myself — by pushing past my comfort zone.”

Q. What steps are you taking now to see those plans through in the coming years?

Right now I’m putting together a multidisciplinary team that will take responsibility for all aspects of compressor and fan design, from the preliminary design phase through to the engine-in-service phase. Having complete design ownership is critical to the prevention of design escapes. Shouldering the responsibility through the entire design cycle also demonstrates commitment to the customer and guarantees a quality product that meets customer expectations.

Q. As leader of the new compressor design team at Hanwha Aerospace USA, what do you think your highest priorities will be?

The members of my team will need to be strongly grounded in the basic physical principles, and willing to learn from each other. Attracting open-minded people who are intellectually humble goes a long way to developing a positive team spirit. I’m looking for intellectual curiosity, an optimistic enthusiasm to learn rapidly in a dynamic environment, humility in the face of adverse learning, and genuine pride in the work.

Also, it’s important to avoid common pitfalls that afflict large organizations, which are typically steeped in a hierarchical chain of command. Such organizations are usually not nimble enough to adopt emerging technologies, resulting in lost opportunities and market share. One common problem is siloing, for example.

Q. Can you share your thoughts about organizational culture? What kind of culture would you like to impart within your compressor design team?

Prior to taking on my current role at Hanwha, I was fortunate to have worked across multiple modules of a jet engine, spanning multiple disciplines over many years. In doing so, I gained a unique perspective from various vantage points.

If one team member fails, the team fails. This is the mentality I want to impart to my new team at Hanwha Aerospace USA — big-picture thinking and shared ownership of the product.

For our team to work together to achieve a common goal, each member will need to understand the challenges across four fundamental engineering disciplines: aerodynamics, structures, and thermal and mechanical design. Since each of these disciplines has its own share of unique challenges, a successful engine design results only from judicious compromises.

About Anil Prasad

With almost three decades of experience as an aerospace engineer, Anil brings a wealth of expertise to his new role at Hanwha Aerospace USA. During his long tenure at Pratt & Whitney, his areas of responsibility included machine learning, aerothermal fluids design systems, compression system aerodynamics, propulsion systems integration, and turbine aerodynamics. A strategic thinker with a knack for solving complex multidisciplinary problems, he is determined to build, energize, and motivate a stellar team to design compressors and fans for Hanwha’s next-generation aero engine in the coming years.

Keep up with Anil on LinkedIn.

More stories on people at Hanwha

Get the latest news about Hanwha, right in your inbox.

Fields marked with * are mandatory.

- Non-employee

- Employee