Hanwha Helps Chemicals Come Full Cycle

Hanwha's Full-Spectrum

Chemical Innovations

Did you know the field of chemistry started in the same century that gave us the calculator, pressure cooker, and Romeo & Juliet? Today, chemistry impacts almost every aspect of daily life, including food production, household goods, healthcare, and industrial manufacturing. The global chemical industry is currently worth about USD 4.7 trillion and is projected to continue growing.

However, the industry is also facing a tipping point because of rising global concerns over environmental protection and sustainable consumption. Chemical manufacturers are increasingly under pressure to develop eco-friendly products and improving recyclability. Those that do foster a circular economy.

Developing Innovative Chemical Products Across Diverse Portfolio

As a chemical manufacturer focused on the needs of the future, Hanwha develops and produces innovative products that are safer for the environment and easier to recycle. Introducing such products to the global market and encouraging their adoption will help foster the growth of a circular economy where disposed goods are turned back into raw materials to produce new goods.

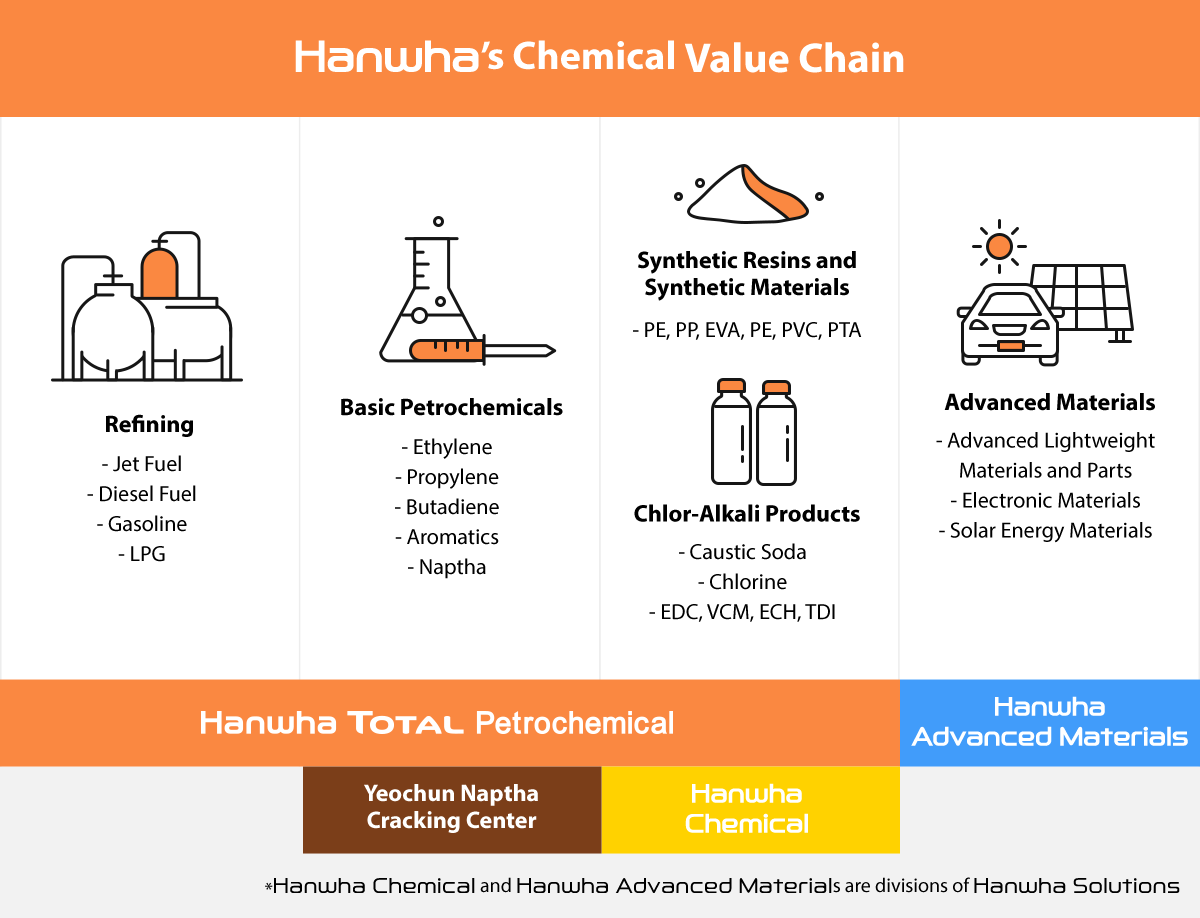

To facilitate this, Hanwha will utilize the vast capabilities of its numerous chemical businesses along the value chain. These businesses produce everything from basic feedstock materials to refined chemicals and more.

Changing How We Produce, Consume, and Dispose for Healthier Ecosystems

Throughout their shared value chain, Hanwha’s chemical and materials businesses are advancing eco-friendly products that can be manufactured sustainably and recycled easily, including bioplastics made of renewable organic materials, more traditional plastics that are easier to recycle, and highly efficient recycling technologies that break goods down to their base components for reuse.

Already, Hanwha’s chemical and materials businesses maintain a comprehensive portfolio of eco-friendly compounds and lightweight materials that help improve environmental sustainability around the world. One significant breakthrough was the commercialization of ECO-DEHCH, a non-toxic plasticizer that is sustainable without sacrificing product quality. Developments such as this mean chemical materials can be produced to be safe for both humans and the environment. Additionally, Hanwha is the global leader in manufacturing Glass Fiber Mat Reinforced Thermoplastics (GMT) and Low Weight Reinforced Thermoplastics (LWRT). As durable as steel – but a fraction of the weight – these materials are used to produce automotive parts that ensure passenger safety while reducing vehicle weight to boost fuel economy.

In addition, Hanwha plans to develop green hydrogen-related technologies by 2025 when hydrogen usage is expected to expand from vehicles to trucks, ships, and even drones. Green hydrogen is a truly eco-friendly energy source produced by renewable solar or wind power that does not emit carbon dioxide. Hanwha is leading the research into water electrolysis technology that produces green hydrogen, having already invested around USD 25.6 million (KRW 30 billion).

As their research and development progress, Hanwha’s chemical and materials businesses will continue making a positive impact and transforming how the world produces, consumes, and disposes goods. These changes will prove beneficial for the environment and help create much healthier ecosystems globally.

- (1) Developing Ways to Make

Plastics Go 'Round and' Round

There's an inconvenient truth we all must confront: Earth has limited natural resources and they're becoming scarcer each day.

- (2) Transforming Plastics to Protect

the Environment :

Hanwha Solutions Developing Eco-Friendly Bioplastics

It’s in your phone. It’s in your office chair. It’s in your computer. And it’s in some of your clothes. It’s plastic – the durable and affordable material for countless applications.

- (3) Hanwha Chemical Envisions

a World of Green Plastic

Hanwha Chemical is taking active steps to address global environmental concerns over the use and disposal of plastics.

Get the latest news about Hanwha, right in your inbox.

Fields marked with * are mandatory.

- Non-employee

- Employee