Clear Skies Ahead: How Hanwha’s Hydrogen Push Could Help Lower Global Emissions

Look at the sky over any major city, and the need for clean, low carbon energy will be crystal clear. The air, however, might not be. As emissions rise globally, exacerbating climate change and leading to record air pollution, pressure is rising to cut carbon and replace fossil fuels before we reach a global tipping point.

While battery powered cars and home solar panels are touted as mainstream solutions, they can’t solve the entire carbon problem. Decarbonizing the globe will require a range of different clean energies, and each one will be better suited to different industries.

One energy source in particular is gaining traction for its ability to fuel some of our most critical and demanding industries: hydrogen. Hydrogen can be burned as a fuel like oil and gas, allowing it to power even hard-to-abate sectors, and yet it produces almost zero emissions. It can be produced from tap water, making it one of the most abundant energy sources on the planet. And with Hanwha investing heavily in making hydrogen greener, more efficient, and easier to store, its latest hydrogen push could be a decisive step towards providing heavy industries with reliable green energy.

What is Hydrogen? And While We’re at it, What is Electrolysis?

Hydrogen presents an interesting solution for a number of reasons. For starters, it’s virtually everywhere. Hydrogen makes up the H in the ever-famous H2O, making it one of the most abundant energy sources in the world. It can be obtained directly from water through what’s called “electrolysis” —the process of using electricity to split water into hydrogen and oxygen, its two basic parts. In most cases, using hydrogen as fuel is incredibly clean, emitting nothing but water vapor and warm air.

Hydrogen also stands out from other renewables in some interesting ways. While making truly “green” hydrogen still requires solar, wind or another form of clean energy, once it’s made it can be stored almost indefinitely. Like oil and gas, its power is derived from within, making it a reliable energy source under any weather conditions. Its energy doesn’t need to be stored in a lithium battery, either, since hydrogen itself is the fuel source. It can be burned for energy just like gas and oil, but without any of the emissions to go with it.

Hanwha, Hydrogen, and the Plan to Cut Carbon

These promising results are why Hanwha is betting big on hydrogen to be the sustainable fuel of tomorrow. Hanwha’s hydrogen plans are broad, but for now it’s putting extra attention on two key business pillars that are helping bring hydrogen into the mainstream.

• Better, safer storage: Hanwha Cimarron—a high-tech materials division of Hanwha Solutions—is revolutionizing hydrogen storage to make it easy, efficient, and reliable.

• Helping businesses cut back: Change doesn’t happen overnight. Hanwha Impact is helping businesses transition at a sustainable pace, making their existing infrastructure more eco-friendly by retrofitting gas turbines to burn a mixture of natural gas and hydrogen. This could immediately result in almost 30% lower carbon emissions, while maintaining or lowering existing regulated nitrogen oxide emissions.

Those plans are coming as calls to slash emissions are on the rise globally. More countries around the world are aligning their goals with net zero targets set by the United Nations (U.N.), which seek to reduce emissions to “close to zero” by 2050. Even the U.S., which has been slow to sign off on major agreements to curb emissions, passed legislation on August 16, 2022 that signaled its biggest victory yet for decarbonization and slowing climate change.

Most countries aiming for net zero targets will likely arrive there through a combination of clean energy sources that include solar, wind, and other renewables. But it’s becoming increasingly clear that hydrogen could play a key part in future clean energy portfolios.

The Many Colors of Hydrogen

Not all hydrogen is created by the same processes. While the final product is always a clean fuel source, there are numerous ways to make hydrogen. In fact, there’s a color for every method of hydrogen production.

Practically any energy source can be used to make hydrogen, with the level of emissions involved in the process as varied as the source. Black and brown hydrogen generally rely on energy from coal. Grey hydrogen uses natural gas or methane to produce hydrogen, with no ensuing carbon capture to rein in the greenhouse gases emitted during the process. This is the most common way of making hydrogen on today’s market. Blue hydrogen also uses natural gas, but makes a significant improvement over the grey variety by capturing and storing the carbon that gets released. Using nuclear energy to create hydrogen is among the cleanest options in terms of emissions, and produces what the industry calls pink hydrogen.

That leaves us with green hydrogen, the name given to hydrogen produced using clean energy from solar, wind turbines, or another sustainable energy source. This is a clean energy source from start to finish, and a key part of Hanwha’s plans for making hydrogen a leading source of clean fuel.

Scientists and Hanwha researchers are also exploring ways of using ammonia to produce clean hydrogen. Ammonia is made up of nitrogen and hydrogen, and researchers have found ways to separate the two using an ammonia splitting catalyst through a process called “cracking.” Since ammonia holds no CO2, there are no emissions released during the cracking process, and the captured hydrogen can then be used as a clean fuel source.

The challenge lies in making green and clean hydrogen cost-effective enough to compete with fossil fuels—a goal that will become easier to reach as solar and wind energy become more efficient. As one of the world’s largest solar panel producers with plans to go even bigger and build out its solar panel value chain, Hanwha occupies a unique position in the industry. It’s one of few companies globally with all the tools to make cost-effective “green hydrogen” a reality. In the meantime though, Hanwha is taking steps to help today’s companies decarbonize gradually.

Into the Mix: Blending Hydrogen and Gas for Cleaner Skies

When most people hear the words “the Netherlands,” they think of perfect wooden windmills on grassy green slopes. But even windy Holland still uses fossil fuels to supply most of its residents with power, making it the sixth highest CO2 emitter in Europe. Hanwha Impact is using hydrogen to help Holland change that story, along with its subsidiary Thomassen Energy, a Dutch turbine corporation.

Thomassen Energy recently secured an order to turn the 123-megawatt Rotterdam Capelle gas turbine—a turbine commissioned in 1982 that provides some 15,000 Dutch homes with power—into a mixed combustion turbine which uses hydrogen in its mix, and reduces carbon in the process. Uniper, the German energy company that runs the turbine, awarded the contract to Thomassen Energy, Hanwha Impact’s new subsidiary, to convert the turbine to burn over 30% hydrogen, along with a mix of its usual natural gas. The hybrid solution will allow Rotterdam to lower emissions and help the Netherlands move closer to going carbon free.

This mixing of hydrogen and natural gas—of old fuel sources that emit carbon, and new ones that don’t—is a crucial step on the way to decarbonizing the energy grid, and one Hanwha is increasing its commitment to. Right now, most turbines that make the transition from purely gas to incorporate hydrogen are burning a mixture of around 30% hydrogen and 70% gas, but there are plans to raise that number gradually and one day even cut out gas entirely. Hanwha’s “hydrogen to gas turbine technology,” or H2GT, retrofits existing LNG-fired power plants’ gas turbines to run on up to 65% hydrogen fuel by volume. The acquisition of Thomassen Energy in Europe and Power Systems Mfg. (PSM) in the U.S., two companies specializing in hydrogen co-firing gas turbine solutions with advanced combustion technologies, is part of Hanwha’s broader plan to expand its portfolio of essential technologies so it can help business take gradual steps towards cleaning up their operations and lowering dependence on gas.

Hanwha’s research into ammonia as a means to make clean hydrogen could also play a part in this transition. Hanwha Impact and Hanwha Corporation are already looking at cracking ammonia as a method for making clean hydrogen, which can then be used for a variety of applications, including the co-firing gas turbines they’re retrofitting for energy providers. An important part of their research is now aimed at finding the cleanest and most efficient way of cracking ammonia, opening up another emissions-free way of creating this clean fuel source.

Co-firing turbine technology does face challenges, one of them being the emission of nitrogen oxide (NO2), a fine dust generated by high-temperature combustion of hydrogen. But these risks fall far below those from burning fossil fuels, and Hanwha is already working on solutions. It currently has a technology that reduces NO2 emissions to less than 9 ppm in 30% hydrogen mixes, putting it far below the 20 ppm deemed acceptable by European standards.

Another hurdle is the safe and stable combustion of hydrogen—a far from simple matter. Hydrogen flames are faster than those from natural gas, leading to challenges with fuel injection known in the industry as flashback. That’s where rapid combustion speeds cause the flame to shoot back up the incoming fuel nozzle, an event best avoided when dealing with large quantities of hydrogen and natural gas.

Hanwha is minimizing those risks, too, and improving stability using technologies like the FlameSheet, operated by its PSM subsidiary. FlameSheet is an aerodynamic structure used in gas turbines to lower the risk of flashback. It allows turbines to function safely and efficiently, even when mixing in large amounts of hydrogen. The FlameSheet also has the added benefit of helping manage NO2 emissions, making it a key tool in Hanwha’s retrofitting strategy, along with its other gas turbine diversification technologies.

Under Pressure: Smarter Storage to Make Hydrogen More Reliable

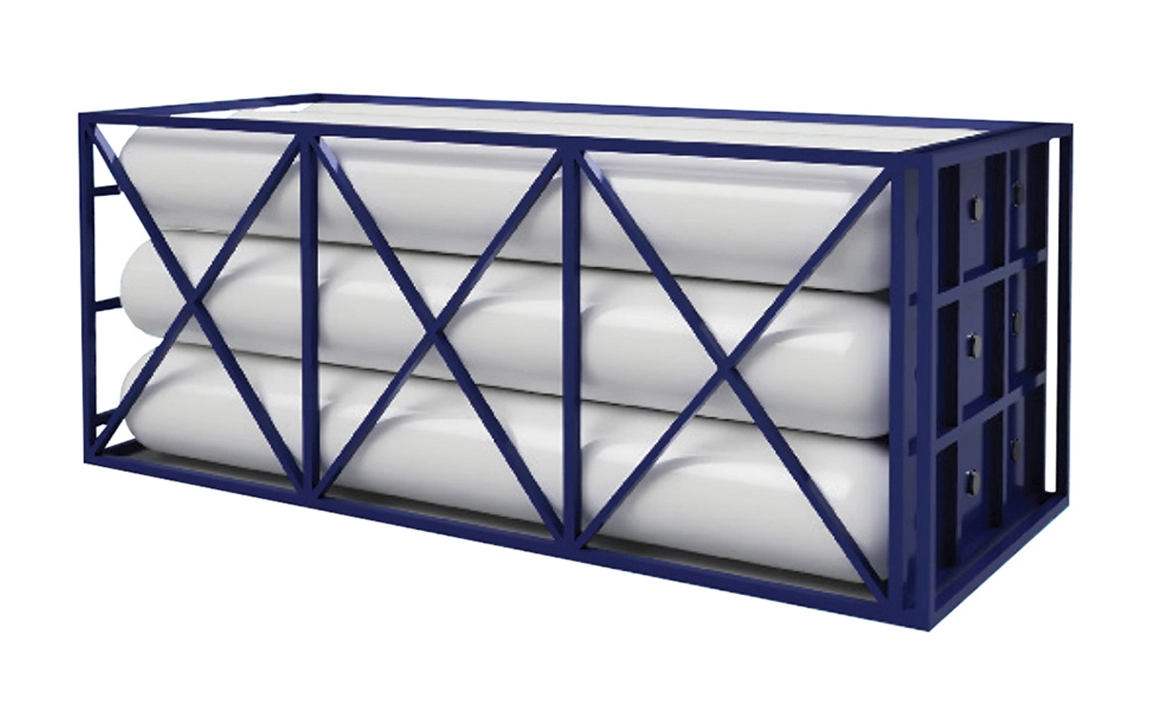

Hanwha Cimarron’s Type IV Neptune Hydrogen Storage Tanks

Making cost effective green hydrogen is the first step in giving various industries a shot at breaking free from carbon dependency. But before any of that can happen, the complicated problem of hydrogen storage has to be solved.

Hydrogen is the lightest molecule in the world. That means hydrogen in its gas form takes up more space than any other gas, leading to tough requirements for storage that include specialized tanks and transport.

This is the same problem that’s puzzled car makers trying to make hydrogen fuel cell vehicles, with onboard storage a logistics hurdle some manufacturers are shying away from. Hanwha sees the challenge as worthwhile, and has secured some of the world’s best hydrogen storage technology by acquiring a company from a former NASA scientist. Hanwha has since integrated the company into its Hanwha Cimarron subsidiary.

Their flagship tank, the 2,000-liter carbon-reinforced “Neptune,” is made in Alabama and can store hydrogen at a walloping 517 bars of pressure, the highest pressure level of any Type IV tank. The Neptune tanks achieve this thanks to a unique “anti-buckling” technology that maintains the tank’s integrity even when 100% of the hydrogen is removed. Most hydrogen tanks will buckle if fully emptied, forcing operators to leave tanks 10% full. Neptune tanks offer a way around this roadblock, streamlining storage and use.

In June 2022, Hanwha Cimarron finalized a purchase order with Shell, the U.S. energy giant, to provide them with Neptune tanks as part of their plans to build an extensive hydrogen refueling infrastructure in California. Hanwha’s high-pressure Neptune tanks will help Shell handle hydrogen transport within its network of stations, accelerating California’s transition to clean energy. Hydrogen is emerging as a cornerstone of California’s future energy supply, with 52 out of 66 refueling stations in the U.S. operating there.

MarketsandMarkets, a research firm with eyes on the energy market, puts projections for the global hydrogen market at $119.2 billion USD by 2027. North America is expected to make up about 13% of that volume, or around $15.5 billion USD. Hanwha Cimarron, with its advanced hydrogen tank technology and growing reputation, could play a major role in that shift, with an ambitious installation plan that includes increasing the number of hydrogen charging stations in California to 1,000 by 2030.

With safety and reliability a major concern for future hydrogen projects, energy partners and governments are putting stock in Hanwha Cimarron’s track record, along with the international safety certificates that organizations like the U.S. Department of Transportation and American Society of Mechanical Engineers have awarded its Neptune tanks. That record of trust has opened the door to other projects, including a green light for Hanwha Cimarron to expand its hydrogen tank business with a new mass production facility in Opelika, Alabama, opening in September 2022.

Hanwha Cimmaron has invested $51 million USD since July 21 into the Opelika plant, which will make around 3,800 ultra-high-pressure hydrogen storage tanks per year.

Clear Skies Ahead

With countries getting serious about climate change and reducing emissions, fuel intensive industries are at risk of falling to the back of the class. Hydrogen is emerging as a fuel that could help them decarbonize, speeding up the overall shift from fossil fuels to clean energy. Hanwha is committed to making this a reality, putting everything behind expanding its portfolios and its capacity to make hydrogen’s production, storage, and transition more practical.

Through key partnerships and unfettered innovation, Hanwha is helping create a real move towards an emission-free energy economy. It’s creating hope that one day you can look at the sky over Beijing, Seoul, New York or London, and you won’t have to wonder whether the push for cleaner energy sources was worth it. It’ll be crystal clear.

Get the latest news about Hanwha, right in your inbox.

Fields marked with * are mandatory.

- Non-employee

- Employee