Submarine cables: The invisible backbone of the digital revolution

Hidden beneath the world’s oceans lies an extraordinary technological feat — a network of cables stretching across the ocean floor for hundreds of thousands of kilometers, serving as our underwater power grid and information superhighway. Submarine cables, also known as subsea cables, are key to accelerating the green energy transition and form the backbone of the communication revolution.

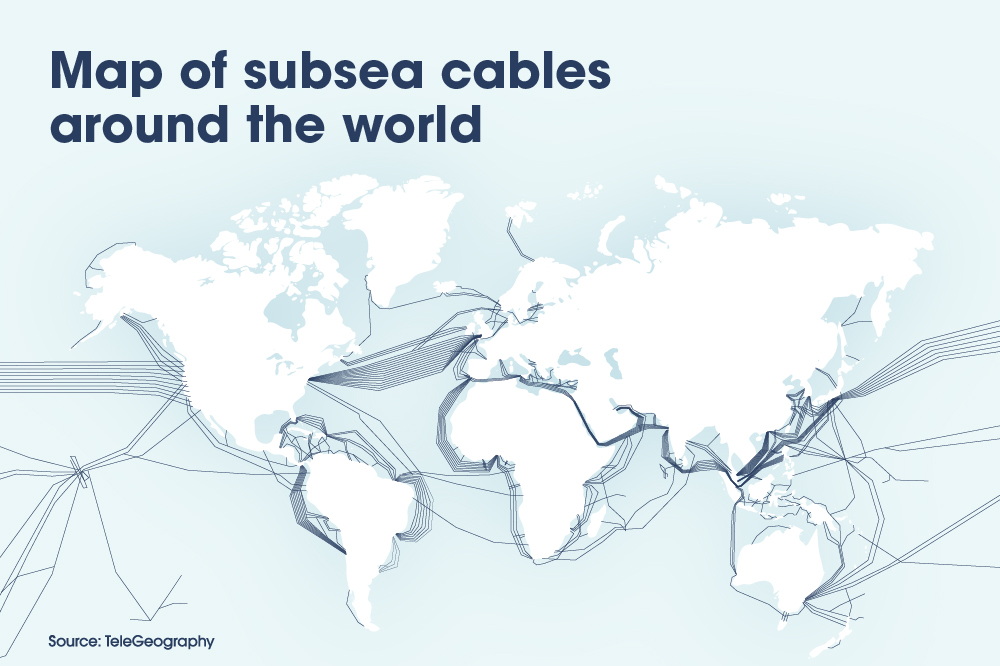

There are currently around 600 in-service and planned submarine cable systems, stretching nearly 1.4 million kilometers across the Atlantic and Pacific oceans and other strategic passages. Subsea power cables, particularly those using high-voltage direct current (HVDC) technology, can transmit substantial amounts of power across long distances. For example, the Viking Link spans around 760 kilometers between the U.K. and Denmark and has a capacity of 1,400 MW, which is enough to power some 1.4 million homes. Subsea telecom cables, meanwhile, are capable of transmitting multiple terabits of data per second and offer the fastest and most reliable method of data transfer available today.

The fact that data and electricity travel between continents through cables not much thicker than a garden hose is a remarkable feat of engineering and multilateral collaboration. Given their pivotal role in facilitating data transfer and expansion of new technologies like AI, subsea cables have become critical to maintaining order and driving economic growth in the digital age. So, what is a submarine cable made of and how is it installed?

Critical subsea infrastructure

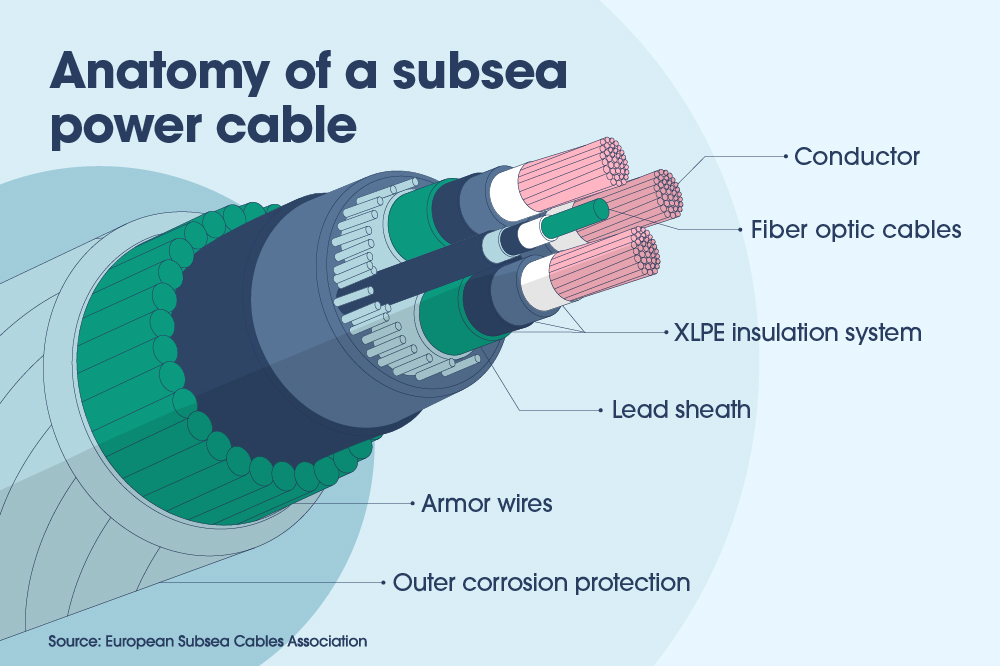

Submarine cables can be divided into two categories: high-voltage power cables and telecommunication cables. High-voltage power cables carry renewable power from offshore energy farms to the land, whereas telecom cables ferry data between continents. Each type has a different core, insulator, and armoring to ensure the cable can perform its intended function.

Each submarine cable contains optical fibers that carry vast amounts of electricity or data to receptors at the other end of the cable. These fibers are sheathed in several layers of insulation to prevent water ingress and protect the cable’s internal components. Materials such as polyethylene are commonly used as insulators as they offer electrical insulation and water-blocking properties, ensuring optimal cable performance and longevity.

When they are laid down, cables nearer to the shore are buried under the seabed for protection. In the deep sea, they are placed on the ocean floor by modified ships carrying thousands of kilometers of cables on board. These cables are slowly laid out on the seabed between continents according to optimized routes.

Cable routes are meticulously planned to avoid fault zones, fishing and anchoring areas, and other potential hazards as they form the central nervous system of the global internet. Damage to these cables, whether accidental or intentional, poses a significant challenge. Man-made threats, such as shipping activities, can inadvertently damage cables through anchoring or trawling. More concerning are deliberate acts of sabotage, where cables are intentionally cut or tampered with. Such actions can cripple communication networks, disrupt financial markets, and even pose national security risks.

In the context of rising geopolitical tensions, the security and integrity of these networks have become a matter of national interest as well as regional and global concern. As such, countries are increasingly focused on ensuring that this critical infrastructure is secure and protected. This involves not only safeguarding the physical cables but also ensuring that they are constructed and maintained by trusted manufacturers and suppliers. By doing so, nations aim to mitigate the risks associated with potential vulnerabilities and ensure the continued reliability of global communication networks.

Optimizing cables in the era of AI

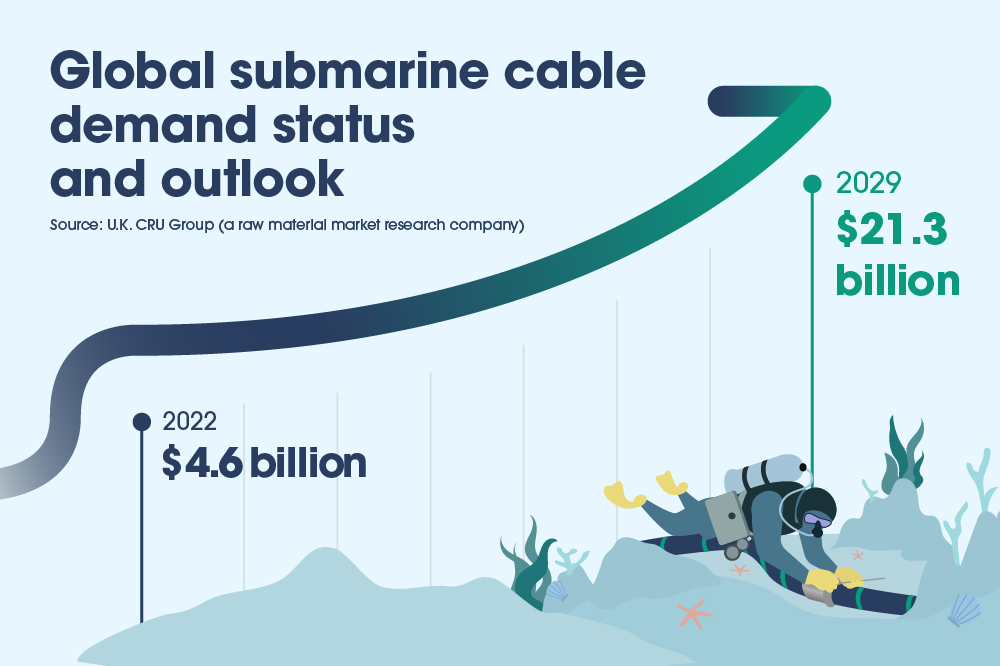

Resilient cable infrastructure can reduce the impact of potential disruptions, and public-private partnerships can play a significant role in its construction, maintenance, and optimization. In fact, the private sector owns and operates a substantial portion of the global submarine telecommunication network, with tech giants estimated to own or lease almost half of all undersea bandwidth between them. In the era of AI and cloud computing, these investments are crucial as the digital landscape evolves, driven by the increasing reliance on AI, edge computing, and Internet of Things (IoT). As these technologies grow, so does the number of data centers needed to support them, requiring a corresponding expansion in power infrastructure to handle AI’s vast energy consumption. In fact, the demand for subsea power cables has already surged in recent years as governments and companies seek ways to transmit power across long distances. And based on the global renewable energy pipeline, the market for undersea power cables is expected to grow substantially, with governments increasingly in favor of cross-border power sharing to accelerate the green transition.

Training large language models, which are at the heart of AI applications, require vast amounts of energy and computational power. And given the surge in AI applications across industries, updating the world’s existing energy infrastructure will become a necessity. Expanding subsea power cable grids would not only help meet the energy demand but also ensure data centers are powered by clean energy. However, laying new subsea power cables is both time-consuming and expensive. Therefore, it is important to first optimize and enhance the existing cable infrastructure to maximize its capacity and efficiency. By enhancing the current energy infrastructure, service providers can better manage increasing energy demands while moving toward building eco-friendly data centers.

Building better cables

As data centers’ demand for electricity continues to rise, power cables will need to carry higher voltages, and advanced insulating materials can help achieve the necessary performance levels by reducing electrical losses while improving overall efficiency and conductivity. Better insulators are therefore crucial for subsea power cables, especially when building high voltage grids for the energy transition.

Hanwha Solutions Chemical Division, with its cable insulation technologies including cross-linked polyethylene (XLPE), Super Extra-High Voltage (SEHV), and Compound LDPE Natural Submarine (CLNS), is helping to build better cables that can more efficiently transmit energy from offshore energy farms to data centers.

In 2022, Hanwha Solutions became the first Korean company to develop EBA, a semiconductive material that is needed to manufacture high-voltage power cables. This year, it reached another milestone by becoming the first Korean company to develop a 400 kilovolt-grade XLPE for cables, positioning itself as a leader in this sector. With an impressive annual production capacity of 110,000 tons, Hanwha’s XLPE production ranks third globally, underscoring its competitive edge in the market.

Hanwha Solutions also introduced SEHV, a new generation of insulators, in response to the ongoing expansion of transmission grid capacity. SEHV is designed for use in 500 kilovolt cables — the highest voltage among commercialized cables available today. The company recently announced it invested KRW 23 billion ($17 million) to expand its extra-high voltage/high voltage (E/HV) grade semiconducting compound production facility by 8,000 tons, in response to the surging demand for power equipment as AI data centers expand worldwide. With this expansion, production capacity will increase to a maximum of 10,000 tons.

Additionally, Hanwha has developed CLNS, a specialized insulator tailored to specific underwater specifications. This material is advantageous to cable manufacturers as it requires less degassing time during production. It also offers long-term stability and superior quality. Hanwha’s CLNS insulators are now being utilized in submarine cable projects across the United States and Europe. This international recognition highlights Hanwha’s ability to deliver cutting-edge solutions for global energy infrastructure needs.

The next digital revolution

Given their ability to transmit large amounts of electricity over long distances, subsea power cables enable the integration of renewable energy sources into the power grid, making them essential for the push toward a more sustainable and resilient energy system. According to CRU, a raw materials analysis firm based in the U.K., the global demand for subsea cables is projected to increase from $4.6 billion in 2022 to $21.3 billion in 2029.

The key to the AI-driven network will be to ensure that undersea, terrestrial and cloud networks continue to seamlessly blend as one cohesive system. This integration is essential for ensuring data centers are powered sufficiently while delivering data to users at unprecedented speeds.

Hanwha is committed to responding rapidly to the growing global demand for energy. By securing advanced technologies that help to build robust grid infrastructure, Hanwha aims to play a proactive role in supporting the next digital revolution and the power needs of the future.

Get the latest news about Hanwha, right in your inbox.

Fields marked with * are mandatory.

- Non-employee

- Employee